The articles in the past explain the following.

- Introduction of the dynamics of an omni-wheel robot

- LQR controller implementation and simulation result

Omni-wheel

I chose this omni-wheel since it is cheap (660 yen for each). Its radius is 24 mm.

Motor

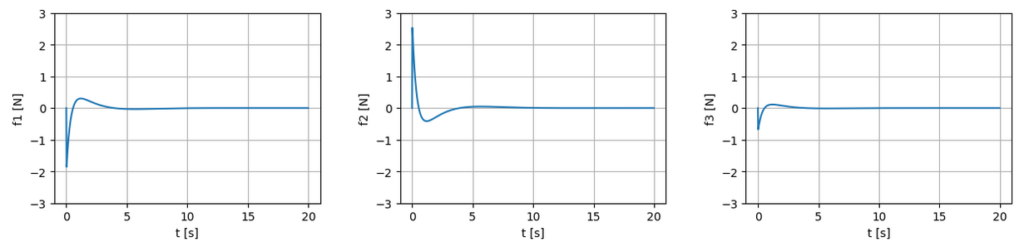

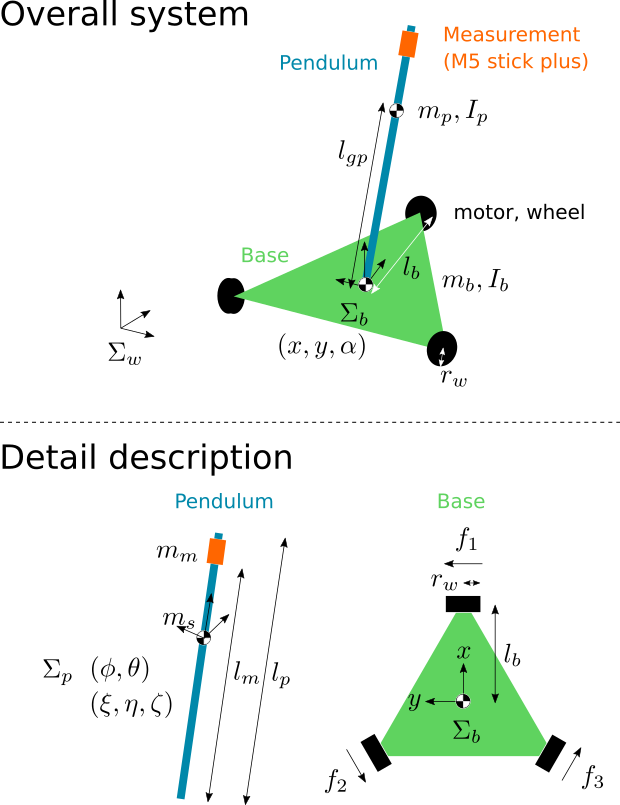

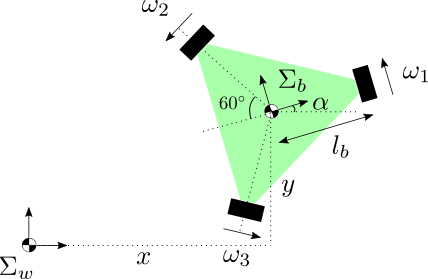

Force for balancing a pole

Based on the simulation result, the motor needs to exert $2.5 \, \mathrm{N}$ at maximum. The simulation is conducted here.

Here, we assume the following physical parameters.

| $m_b$ | mass of omni-wheel robot body | $1.0 \, \mathrm{kg}$ |

| $l_b$ | length between wheel and the center of mass | $0.12 \, \mathrm{m}$ |

| $r_w$ | radius of omni-wheel | $0.024 \, \mathrm{m}$ |

| $I_{b,zz}$ | Inertia of omni-wheel robot body about $z$ axis | $0.0035 \, \mathrm{kg \cdot m^2}$ |

| $m_p$ | mass of pendulum | $0.01 \, \mathrm{kg}$ |

| $l_p$ | length of pendulum | $2.0 \, \mathrm{m}$ |

The mass of the omni-wheel robot body is estimated from the information

- motor mass: $0.1 \, \mathrm{kg} \times 3 = 0.3 \, \mathrm{kg}$ (It varies depending on the chosen motor)

- battery mass $0.023 \mathrm{kg} \times 12 = 0.276 \, \mathrm{kg}$

- wheel mass $0.039 \, \mathrm{kg} \times 3 = 0.117 \, \mathrm{kg}$

, whose sum equals to $0.693 \, \mathrm{kg}$. Considering the mass of the circuit board and the omni-wheel body frame, I assume that the total body mass is about $1 \, \mathrm{kg}$.

Regarding the wheel’s radius $r_w = 0.024 \, \mathrm{m}$, the maximum torque we need is $\tau_b = 2.5 \times 0.024 = 0.06 \, \mathrm{Nm}$.

Friction force

Also, friction force should be considered. Referring to this website, the rolling friction coefficient would be around $\mu$ = 0.02 (I referred to the value for “car tires on tar or asphalt”).

The friction force the robot needs to exert is calculated as $\mu m_b g$. Here, $m_b = 1.0 \, \mathrm{kg}$ is the robot’s weight, and $g = 9.8 \, \mathrm{m/s^2}$ is the gravitational acceleration constant.

\begin{align}

\mu m_b g = 0.02 \times 1.0 \times 9.8 = 0.196 \fallingdotseq 0.2 \, \mathrm{N}

\end{align}

Required torque is calculated by multiplying $r_w$.

\begin{align}

\tau_f = r_w \times \mu m_b g = 0.024 \times 0.196 = 0.0048 \fallingdotseq 0.005 \, \mathrm{Nm}

\end{align}

In total, we need around $\tau = \tau_b + \tau_f = 0.065 \, \mathrm{Nm}$.

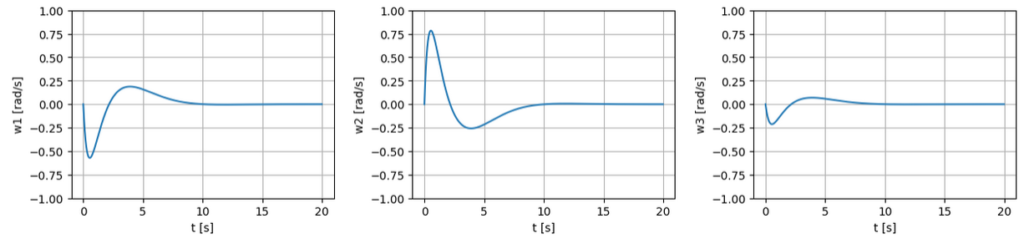

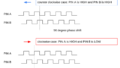

Wheel Velocity

For the calculation of each wheel velocity, utilize the following equation.

\begin{align}

\begin{bmatrix}

\omega_1 \\

\omega_2 \\

\omega_3

\end{bmatrix} =

\begin{bmatrix}

0 & 1 & l_b \\

-\frac{\sqrt{3}}{2} & -\frac{1}{2} & l_b \\

\frac{\sqrt{3}}{2} & -\frac{1}{2} & l_b

\end{bmatrix}

\begin{bmatrix}

\cos \alpha & \sin \alpha & 0 \\

-\sin \alpha & \cos \alpha & 0 \\

0 & 0 & 1

\end{bmatrix}

\begin{bmatrix}

\dot{x} \\

\dot{y} \\

\dot{\alpha}

\end{bmatrix}

\end{align}

The left $3 \times 3$ matrix converts velocity from the body frame to the wheel frame, and the right $3 \times 3$ matrix converts velocity from the world frame to the body frame.

This paper explains the kinematics of an omni-wheel robot in detail.

During the simulation, the wheel velocity is found to be less than $1.0 \, \mathrm{rad/s} = 9.54 \, \mathrm{rpm}$. Revolutions per minute (rpm) is calculated by $\omega_{\mathrm{rpm}} = \frac{60 \times \omega_{\mathrm{rad/s}}}{2 \pi}$ or by this website.

We have come to the conclusion that revolutions per minute is at most $10 \, \mathrm{rpm}$.

Comparison

The following table shows the four motor candidates.

| Model number | GA25-371 $400 \, \mathrm{rpm}$ | GA25-371 $250 \, \mathrm{rpm}$ | GB12-N20B $155 \, \mathrm{rpm}$ | GB12-N20B $105 \, \mathrm{rpm}$ |

| Rated voltage | $12 \, \mathrm{V}$ | $12 \, \mathrm{V}$ | $6 \, \mathrm{V}$ (range: $3 \, – \, 12 \, \mathrm{V}$) | $6 \, \mathrm{V}$ (range: $3 \, – \, 12 \, \mathrm{V}$) |

| Reduction ratio | $19$ | $21$ | $100$ | $150$ |

| No-load speed | $400 \, \mathrm{rpm}$ | $250 \, \mathrm{rpm}$ | $155 \, \mathrm{rpm}$ | $105 \, \mathrm{rpm}$ |

| Rated torque | $0.264 \, \mathrm{Nm}$ | $0.421 \, \mathrm{Nm}$ | $0.068 \, \mathrm{Nm}$ | $0.098 \, \mathrm{Nm}$ |

| Rated speed | $230 \, \mathrm{rpm}$ | $140 \, \mathrm{rpm}$ | $90 \, \mathrm{rpm}$ | $60 \, \mathrm{rpm}$ |

| Hall feedback resolution | $234.3$ | $374$ | $198.6$ | $301.9$ |

| Weight | $0.099 \, \mathrm{kg}$ (ref | $0.099 \, \mathrm{kg}$ (ref | – | – |

All of them suffice the requirement

- the maximum torque should be larger than $0.065 \, \mathrm{Nm}$.

- the maximum wheel velocity should be larger than $10 \, \mathrm{rpm}$.

For example, if we use GA25-371 at $400 \, \mathrm{rpm}$, the wheel can move at a speed of $1.0 \, \mathrm{m/s}$. This results in a translational motion speed of $0.87 \, \mathrm{m/s}$ (because of the omni-wheel robot’s structure, $\frac{\sqrt{3}}{2}$ is multiplied).

Torque unit conversion from $\mathrm{kg \cdot cm}$ to $\mathrm{Nm}$ is done here ($9.8 / 100 \, \mathrm{kg \cdot cm} = 1 \, \mathrm{Nm}$).

After all, I determined to buy GA25-371 $400 \, \mathrm{rpm}$ and GB12-N20B $155 \, \mathrm{rpm}$. Here, I prioritized the rotational speed of the motors.

コメント