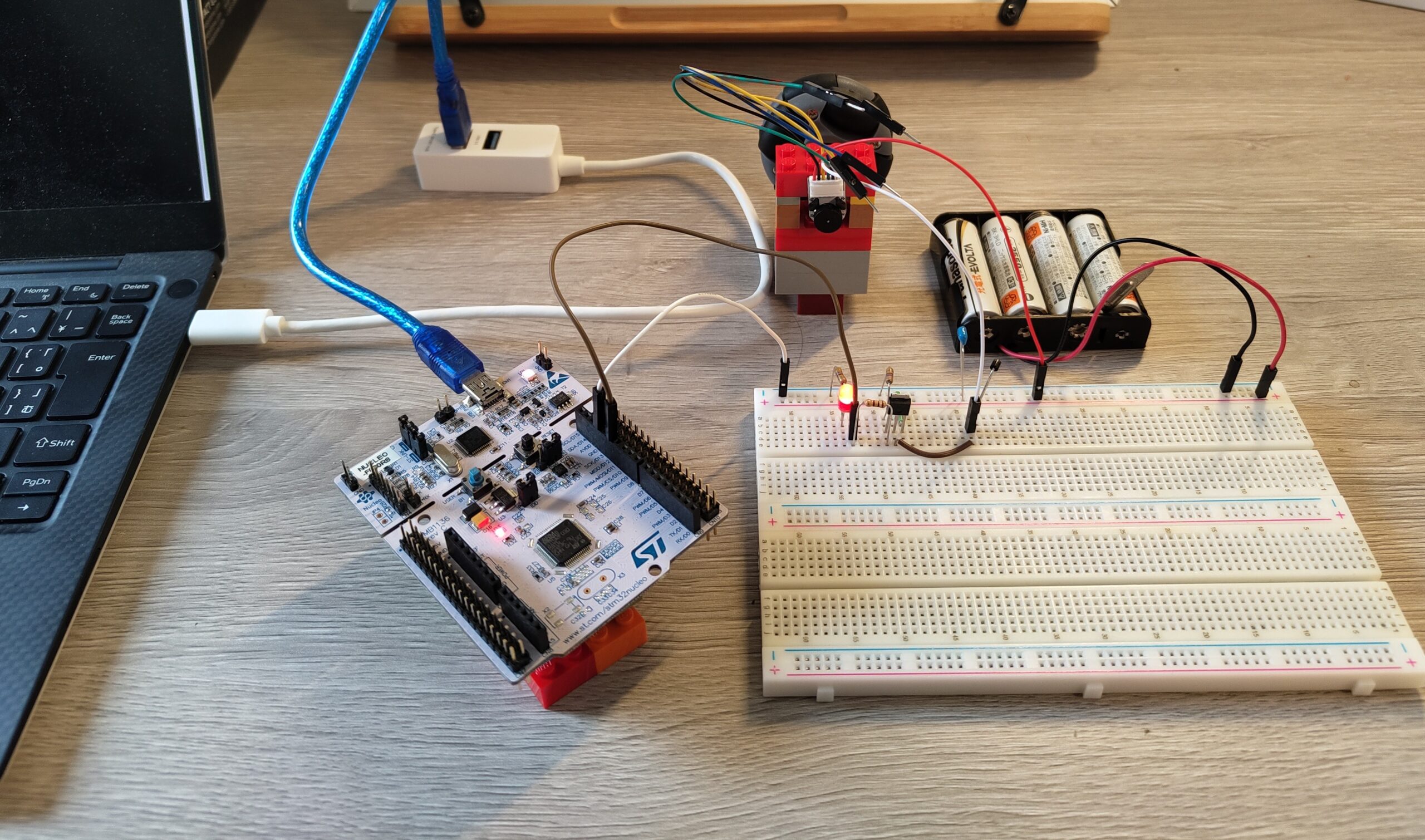

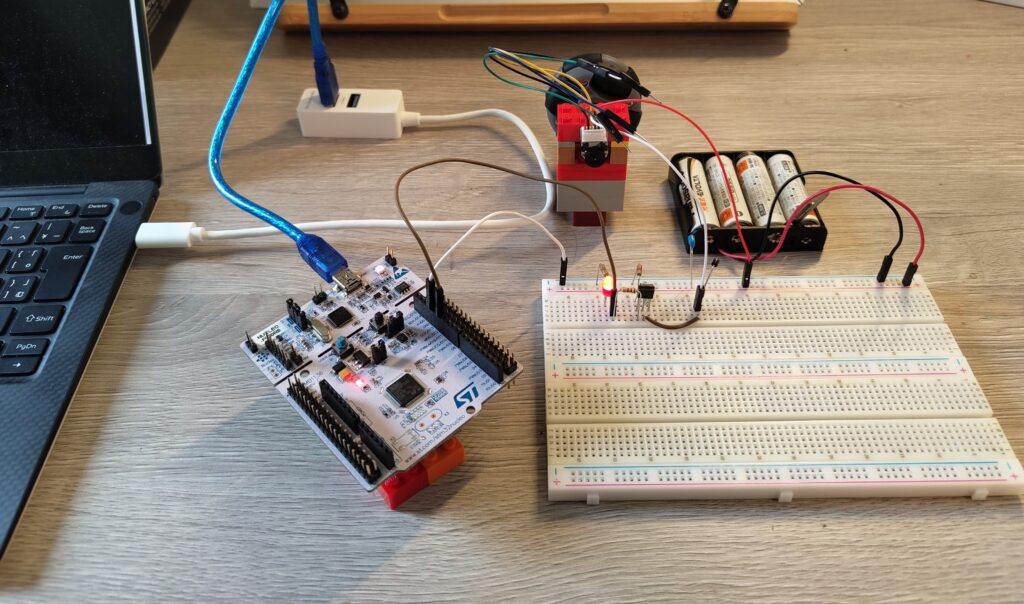

Outcome is this!

Experimental environment

The machine spec and motor information are described in the table.

| host PC | DELL xps 13 |

| host OS | ubuntu 22.04 |

| IDE | STM32CubeIDE 1.13.1 |

| microcontroller | NUCLEO STM32 F030R8T6 |

| motor | GB12-N20B (chosen in this article) |

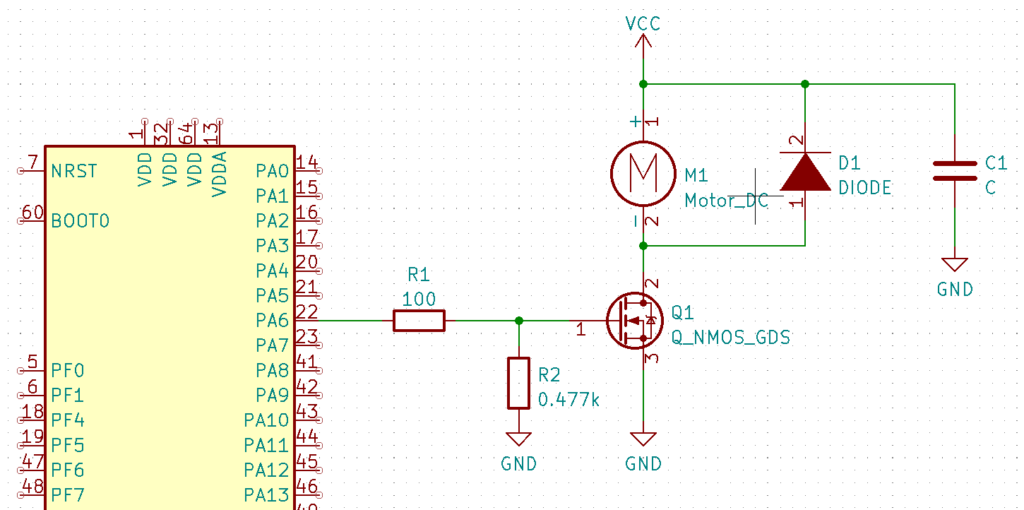

The circuit is expressed as follows. This is based on the article about writing a schematic of a drone.

STM32 configuration and source code

Configuration

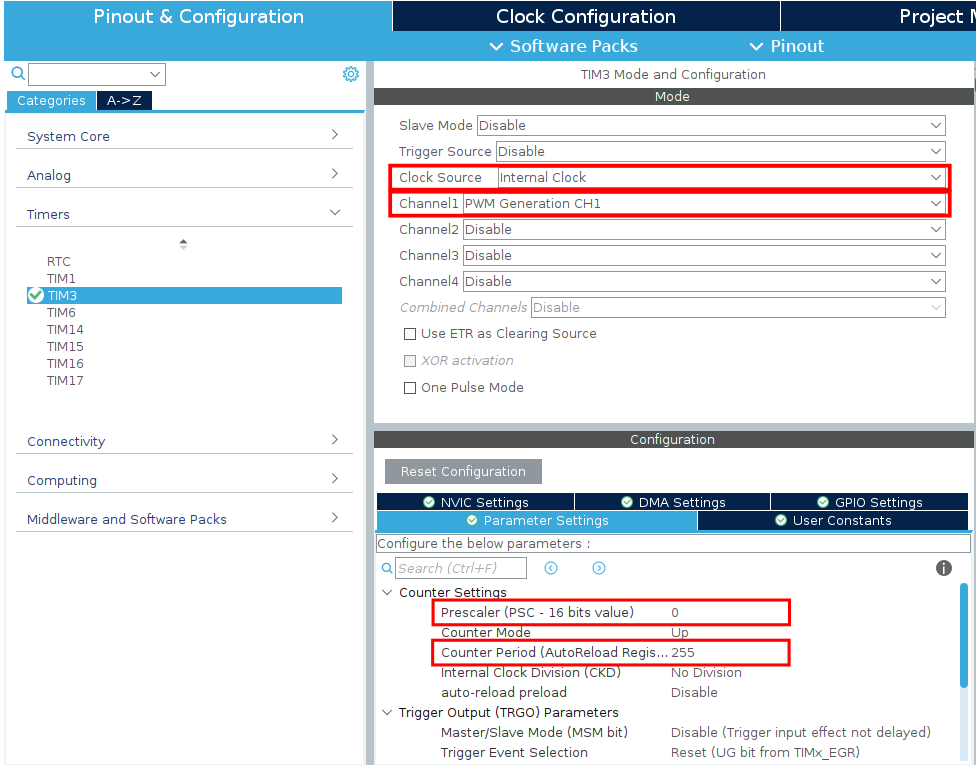

Choose TIM3 this time since Timer 3 can be used in all of STM32 series (ref).

I set the following configurations.

| Clock Source | Internal Clock |

| Channel 1 | PWM Generation CH1 |

| Prescaler | 0 (default) |

| Counter Period | 255 (8 bit) |

A screenshot of the above configuration is shown here. This is specified in a .ioc file.

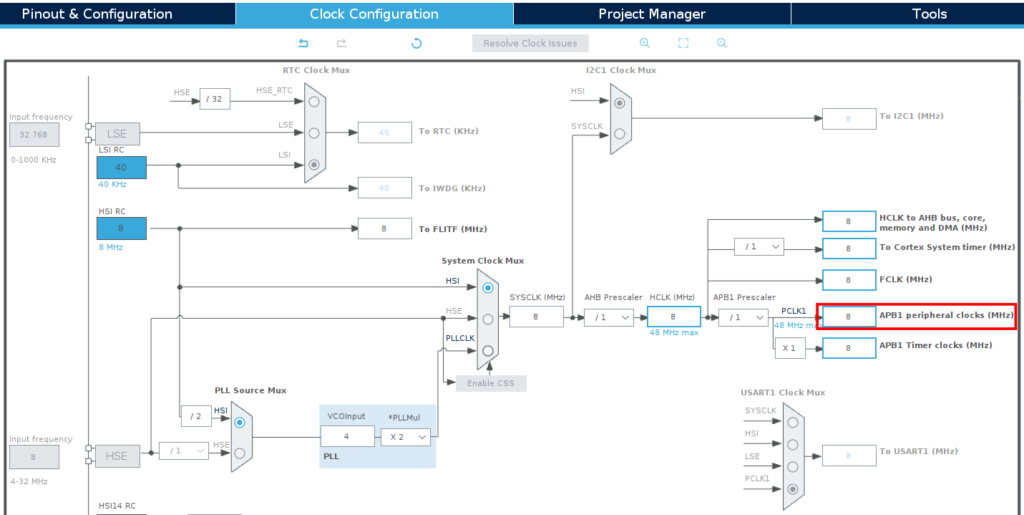

PWM frequency is calculated as follows (ref).

$$ \mathrm{PWM \ frequency} = \frac{\mathrm{frequency \ of \ the \ clock}}{\mathrm{prescaler} \times \mathrm{counter \ period}}$$

※ As for STM32CubeIDE setting, we should subtract $1$ from the prescaler and the counter period values because they are 0-based (ref).

Here, the prescaler is $1$, the counter period is $256$, and the frequency of the clock is $8 \, \mathrm{Mhz}$, thus the PWM frequency is $31.25 \, \mathrm{kHz}$.

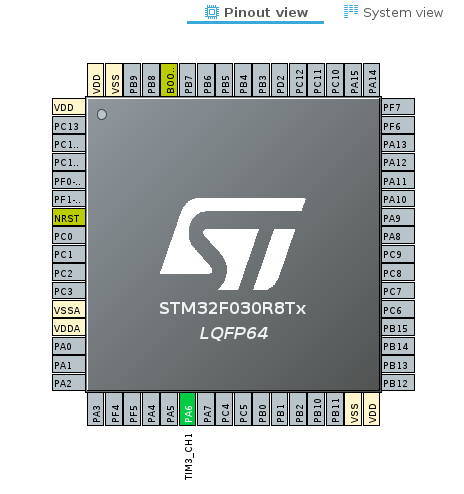

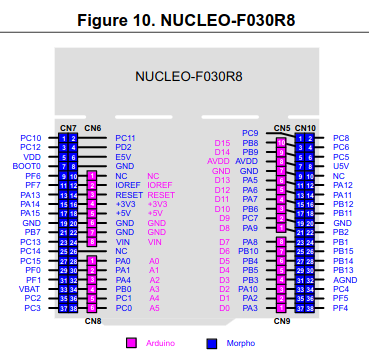

After setting the above configuration, automatically PA6 was chosen for the timer output PIN.

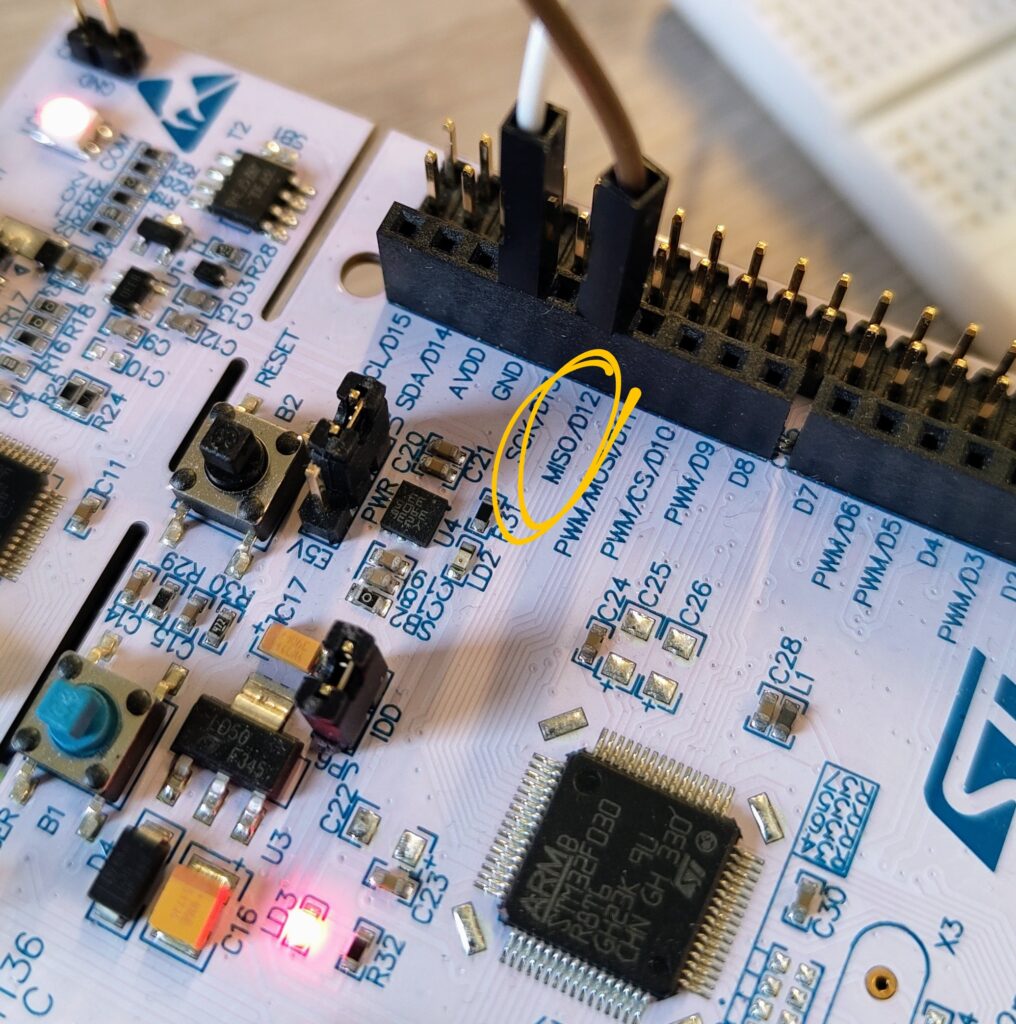

Referring to PIN layout shown below, we need to connect D12 to use PA6 for timer 3 channel 1.

Source code

The main source code is uploaded on github repository.

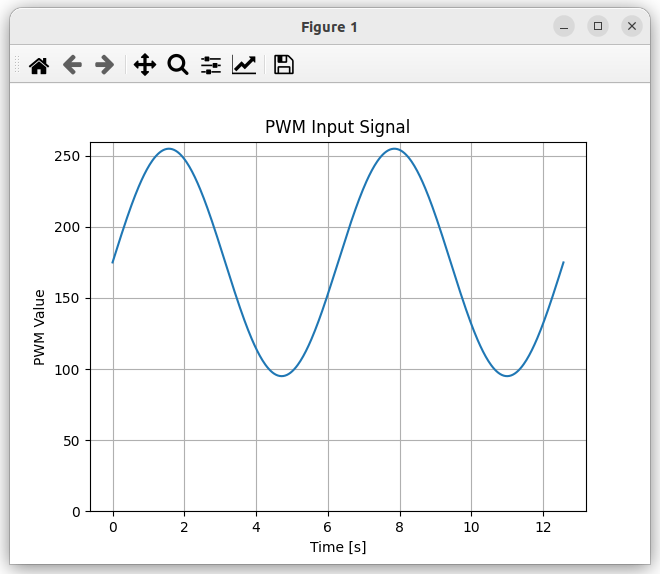

The point is the generation of PWM signals depending on time and creates a sine wave for PWM input. The data variable ranges from $95$ to $255$ and the period of the sine wave is around $6.28$ seconds.

while (1)

{

double t = HAL_GetTick() / 1000.0; // ms -> s

const double gain = 80.0;

const double offset = 175.0;

int data = gain * sin(t) + offset;

__HAL_TIM_SET_COMPARE(&htim3, TIM_CHANNEL_1, data);

printf("data: %d \n", data);

/* USER CODE END WHILE */

/* USER CODE BEGIN 3 */

}The function __HAL_TIM_SET_COMPARE() can change the PWM value dynamically (ref).

Reference

Some references are in Japanese but are quite well documented.

コメント